Humans have amazing abilities.

Highly dexterous hands, joints that can rotate and flex to many angles, highly adept sense of balance, and the ability to hone and polish muscle movements to accomplish tasks in incredible ways.

And the more a person can get done in a shorter amount of time, while still doing a good job, and managing risks, all the better.

But in spite of all this there are things that we can observe about getting things done:

– humans can be injured

Some tasks are more risky than others, especially when they involve:

– heights

– significant speed

– significant weight

– objects of unwieldy size

– many repetitions especially of the same type, or that cause unnatural stretching or joint positions, that can cause physical injury over time.

– humans have speed, strength, stamina, and energy limitations that limit the amount of work that can be done in a set period of time.

Now everything has limitations, but humans benefit from tools that help them augment their abilities and overcome limitations in material strength (for humans, muscles tear, bones break) and energy (only so much energy is available at one time and re-charging takes time) – the two core limiting factors of productivity.

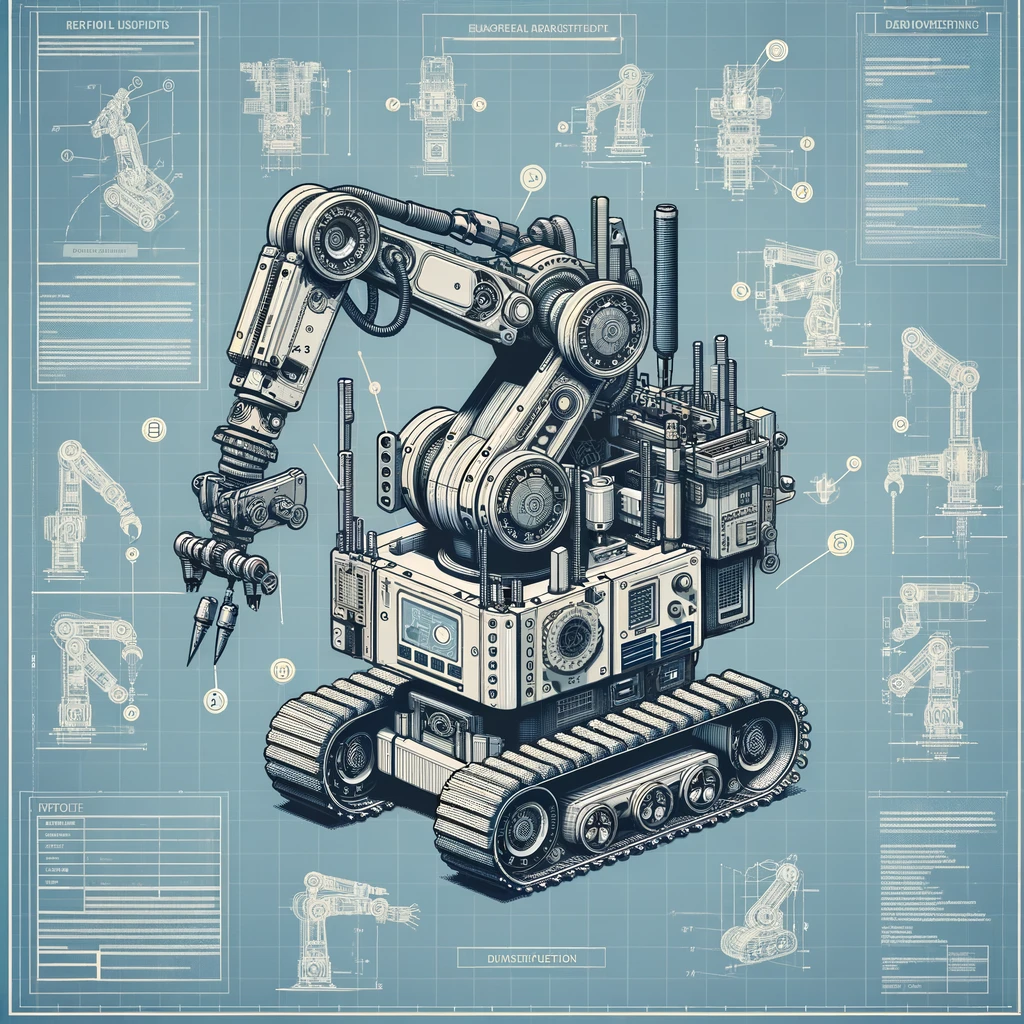

Making a tool or machine that can do a task faster and at least as good as a skilled human can be a challenging engineering problem, where it has to be determined if it is worth is based on:

– the level of risk to a person per task or the risk over time

– how often of a task has to be done

– the value of the task to be done

Example Application

Say you have to put up dry wall in a building.

While you could have an expert energetic dry wall installer put up the sections fairly quickly.

An argument could be made that a specialized machine or robot would be more productive by putting up more sections in less time with minimal risk to the installer, especially for sections that require a ladder or lift to install.

Implementation

The requirements would be that the installation system would:

– be faster without breaking or damaging the material being installed

– at least as accurate

– use the adhesive or fastener correctly and accurately

– be simpler to use and set up than doing manually

General Task Know How

It can be argued that someone who has never done something doesn’t know what they are talking about and that a engineered solution can’t possibly be as good as a skilled human.

But not being able to imagine how something could be done better isn’t a real argument of why it couldn’t be done better.

Until there is an actual proposed solution that fails in some provable way, we can’t know that it can’t be done better.

There could be some technology or applied physics that we are not aware of that is at a reasonable enough cost for a single job or spread over many jobs that could make it possible and feasible.

A good designer, maker, or engineer, with formal training or not, uses their existing knowledge and experience to evaluate the feasibility of a potential solution, in both physical practical terms and financially.

Creating solutions isn’t limited to people with direct task experience or a particular educational background.

Those things may help, or they may not in creating a good tool.

True practical productivity is a combination of factors, the thing is to zoom out enough to find a practical solution.